Automation That Accelerates Results

In today’s economy all companies need continued commitment to customer satisfaction by, decreasing costs, increasing quality of its products and on time delivery. US Engineering’s vision remains clear, to meet or exceed each of our customers expectations.

Our goal is to solve your most challenging production issues through a variety of automation methods utilizing the most capable, creative and committed people our industry has to offer. US Engineering has over 30 years experience in the automation industry.

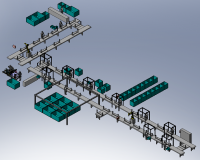

USE will solve your manufacturing demands by utilizing our experience in Robotic applications, Material Handling, Welding, Assembly, Fastening, Hard Automation and More. In every case, we do the complete job – leaving you with a turnkey system that meets or exceeds your expectations.

To request more information on our Flexible Automated Systems click here.

|

WeldingOur core business at US Engineering is welding systems including Robotic MIG/Arc, Resistance and Projection welding. Our systems are designed for high volume welding production runs. Our engineering staff will work with you to design and build an automated welding system that will not only meet your expectations along with maximize cost savings, but ensure consistency, quality, and safety, for high volume welded parts . |

|

Material HandlingU.S.E. will custom design a turnkey Material Handling System capable of manufacturing, assembling and inspecting your product. By combining assembly and vision automation in your material handling processes, not only will you decrease your processing time but, you will control the process flow and improve the quality of your product. |

|

Robotic Work CellsA Robotic Work Cell from U.S. Engineering is all about Reduction, a reduction in scrap, labor, cycle time, product defects and safety issues. A big advantage is the ability to retool the work cell to keep up with changing product and manufacturing needs. We use the latest in simulation software to insure each robotic cell we engineer is capable of living up to our customer’s expectations. From Fanuc to ABB, we can provide you with cost effective solutions in the following areas:

|

|

AssemblyIs your manual assembly not able to keep up with sales volume? Is the product you manufacture labor intensive? Or do you have to continually move your sub-assemblies from station to station? U.S.E. can design and integrate a custom solution that will improve you manufacturing process thereby lowering the cost to produce your product. From small assembly machines to a complete assembly Line, U.S.E.’s innovative approach to solving manufacturing problems can help you improve efficiency, reduce labor costs and increase profitability. |